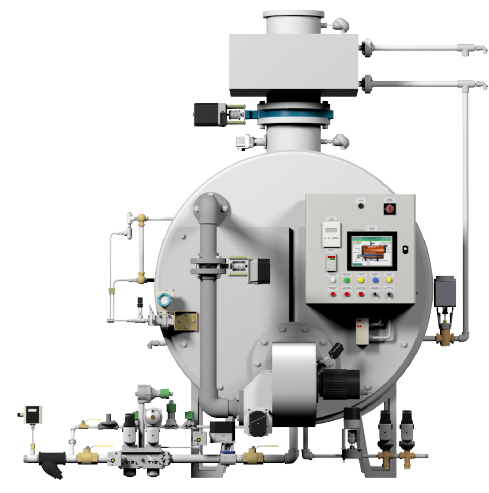

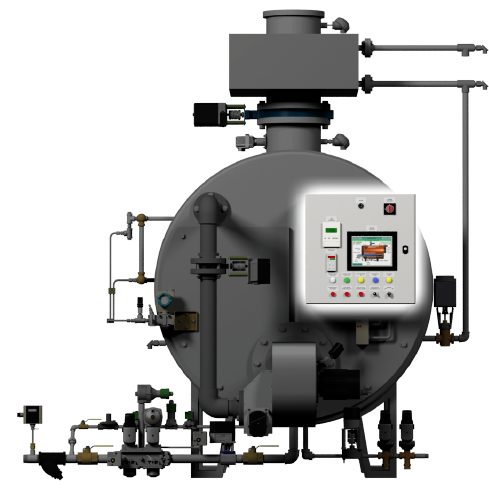

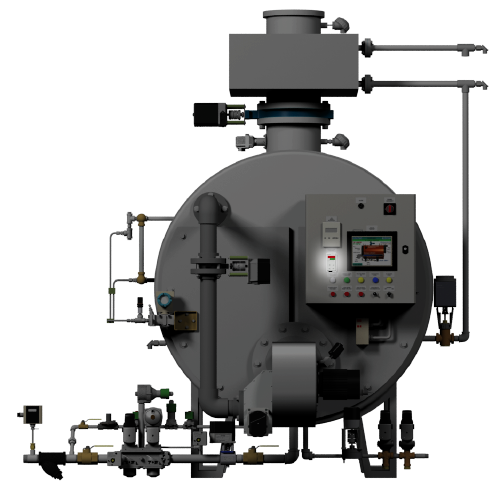

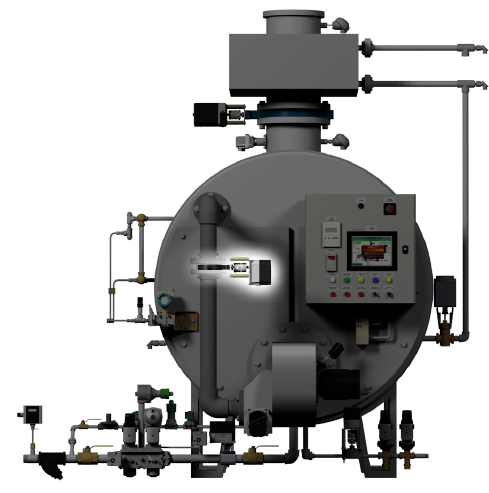

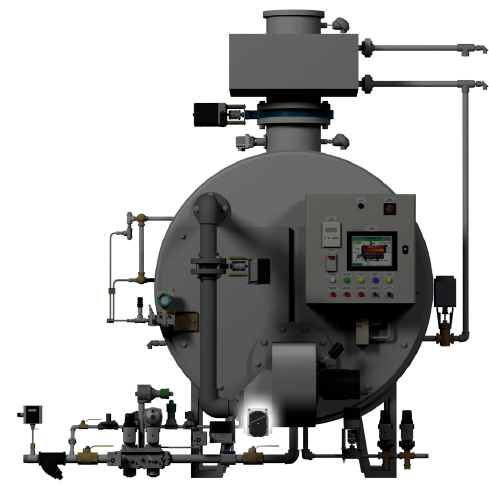

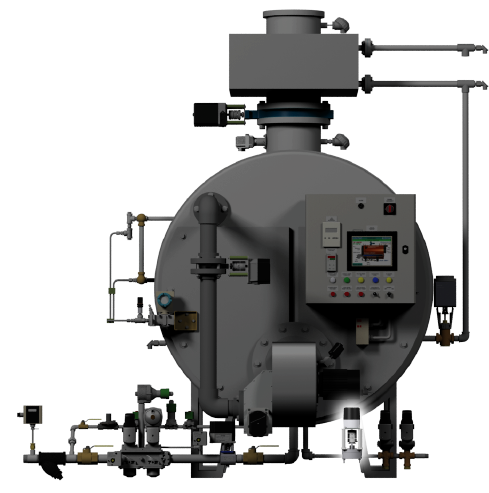

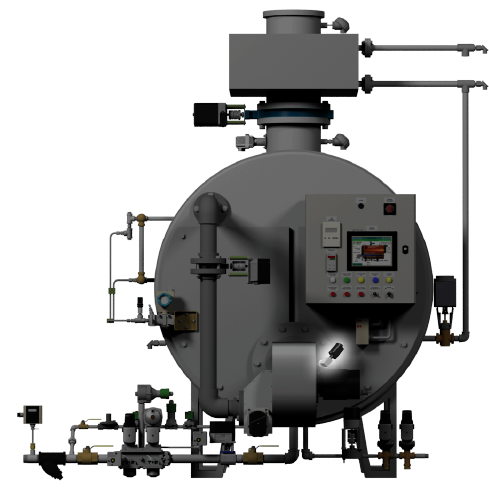

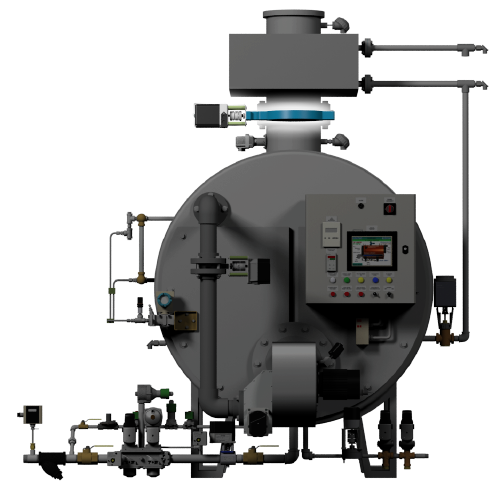

World-class system, support and performance.

Each of the menu selections below highlight control components that are crucial for efficient and reliable boiler operation. Each selection offers photos, information and hyperlink for more information:

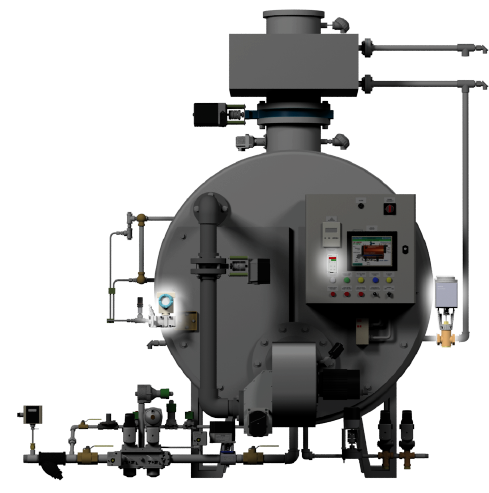

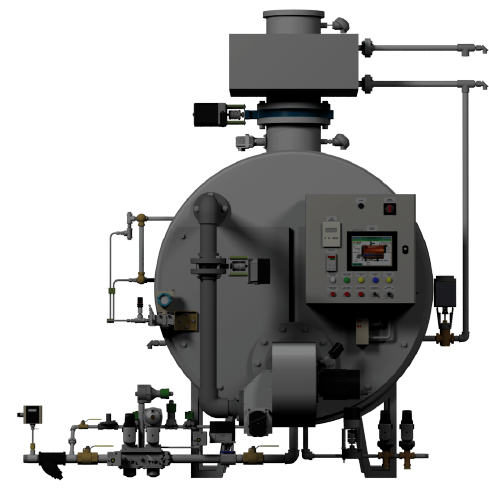

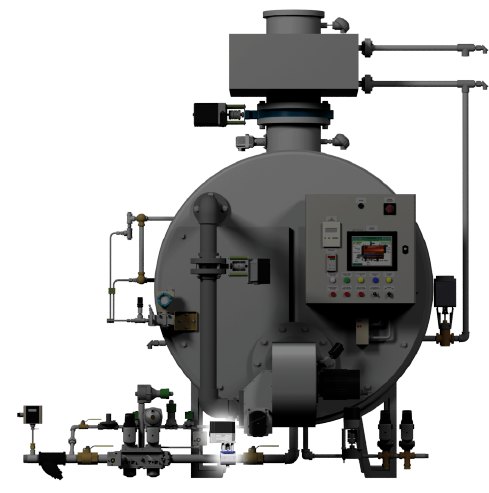

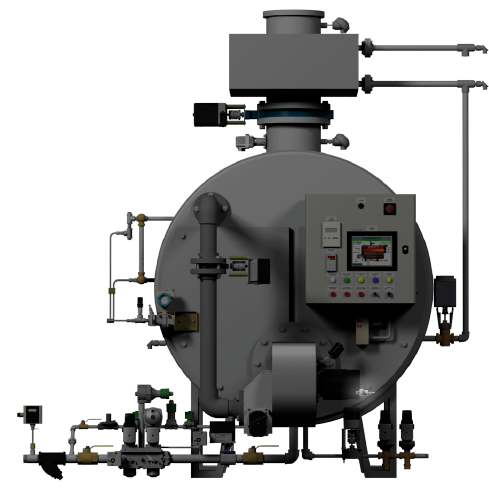

World-class system, support and performance.

Each of the menu selections below highlight control components that are crucial for efficient and reliable boiler operation. Each selection offers photos, information and hyperlink for more information:

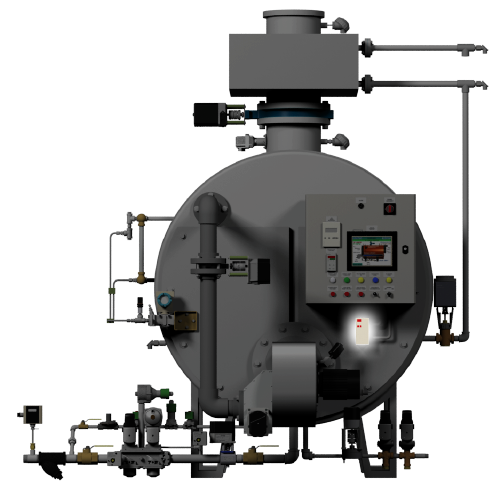

LMV5 Linkageless System

The LMV5 Linkageless Burner Management System sets the standard high – from easy installation, programming and commissioning to reliable, proven control. The LMV5 forges new ground delivering a fully integrated system that is not only easy to install and use, but also provides improved burner performance and efficiency and ensures safe operation.

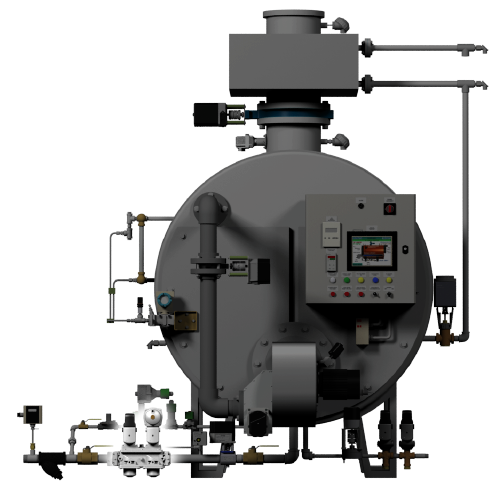

Gas Shut Off Valves

The SKP series electro-hydraulic actuators are used in combination with any VG series gas valve. This modular approach creates a matrix of valve combinations, allowing manufacturers to meet varied capacity and pressure regulation requirements.

Oil Shut Off Valves

The VOG series oil shutoff valve provides safety shutoff for commercial and industrial oil burner applications. NEMA 4, proof of closure switch, and 300 PSI pressure rating are all standard on the VOG oil shut off valve.

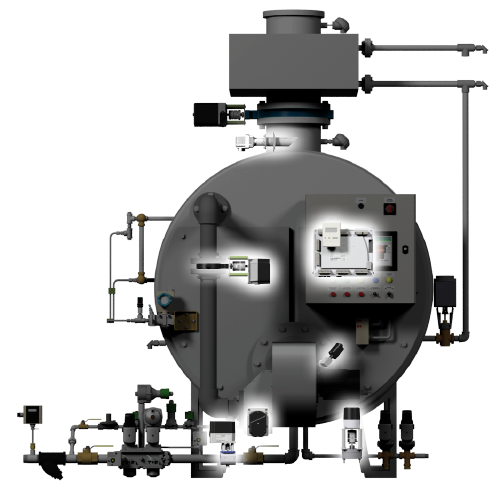

Touchscreen/Combustion Enclosure

TS… series touchscreen kits provide a human machine interface (HMI) when used with a LMV linkageless system. Each kit provides boiler burner data collection and trending for a hydronic or steam boiler. Combustion Enclosures provide a simple, cost effective, and easy to install LMV5 panel.

Modulating Water Level Control System

The SCC Inc. Electronic Water Level Control System maintains a consistent water level, which is crucial for efficient, reliable boiler operation. The SCC Inc. Modulating Water Level Control System offers more efficient boiler operation, with minimal boiler water carryover, and reduced thermal shock to boiler. For boilers with rapidly fluctuating steam loads, the SCC Inc. system has the capability to include dual-element control, minimizing boiler drum swell and shrink effects.

Further Information on Modulating Water Level Control System

O2 Trim Sensor

SCC Inc. offers the most advanced O2 trim on linkageless control systems, designed for Ultra Low NOx (<9 ppm) burners. Further Information on O2 Trim Sensor

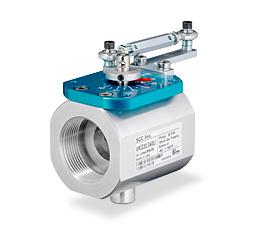

Gas Butterfly Valves

UL approved, ½” through 4” NPT threaded VKG butterfly valves are offered in full, medium, or reduced port versions to optimize pressure drop and flow control. With 25 PSI operating pressure rating, the VKG valve is applicable in commercial or industrial applications.

Temperature/Pressure Controller

The RWF5 optimizes temperature or pressure control on modulating burners. With Modbus, setpoint changeover, setpoint shifting, outdoor air reset and limit comparator, the RWF55 is the premier control on boilers. Hot Standby and Low Fire Hold are powerful tools on boilers with both a RWF5 and LMV5 controls.

FGR Valve Actuator Assembly

FGR VA high temperature versions for flue gas recirculation (FGR) or hot air up to 900º F.

Air Actuator with Coupling and Bracket

SCC couplings and brackets are designed for easy installation of actuators. Couplings allow up to 0.08” parallel displacement AND up to 4 degrees angular misalignment.

Further Information on Air Actuator with Coupling and Bracket

Oil Control Valve Actuator Assembly

A full complement of Valve-Actuator (VA) assemblies are available. Standard VA assemblies are assembled, tested and shipped quickly upon receipt of order.

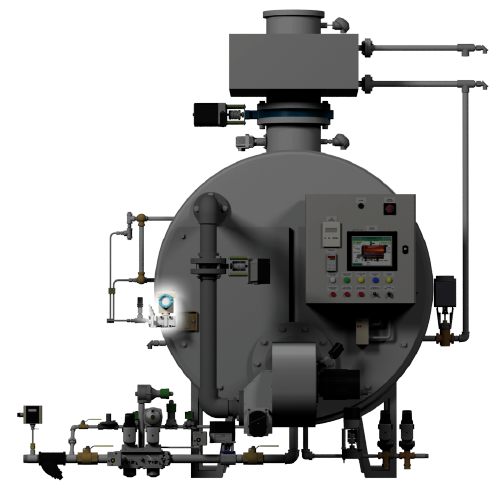

Differential Pressure Transmitter

The SCC Inc. Electronic Water Level Control System maintains a consistent water level, which is crucial for efficient, reliable boiler operation. The SCC Inc. Differential Pressure Transmitter provides more efficient boiler operation, with minimal boiler water carryover, and reduced thermal shock to boiler.

Temperature/Pressure Sensors

SCC Inc. offers a full line of accurate and reliable temperature or pressure sensors. 7MF… series pressure transducers accurately measure the pressure of liquid, gas, or vapor. QAx… temperature sensors (RTD’s) are easy to install and suitable for up to 900º F.

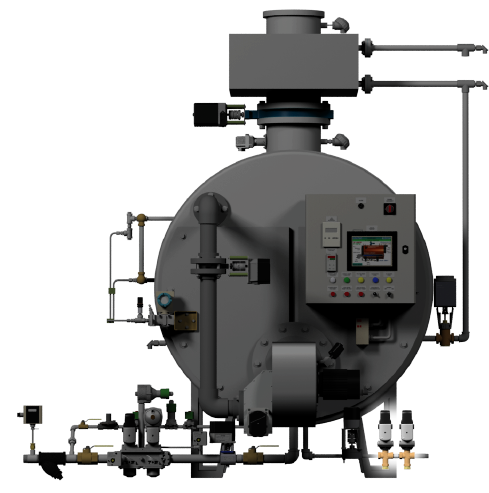

Pressure Switches

SCC Inc. Series QP… pressure switches are designed for gas or air pressure supervision on commercial and industrial burner applications. Automatic and manual reset versions, in a wide range of available pressures add to SCC’s extensive combustion control line.

Flame Detector

Flame detector options for the LMV5 linkageless system includes the QRI IR detector or the QRA75 Self Check UV Scanner. With both mounting and thermal barriers, these flame detectors provide both installation and application options.

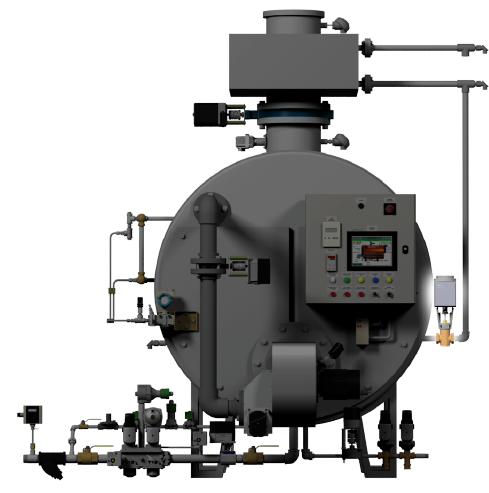

Variable Frequency Drive

Variable Frequency Drives preprogrammed for the LMV linkageless application are options which provides a simple method for burner operational savings.

Feedwater Valve

½” to 6” feedwater valves are available as part of the SCC Inc. Electronic Water Level Control System.

VFD Feedback Sensor

Incorporated with a LMV5, a VFD control with actual motor RPM speed sensor provides reliable, efficient and safe control of the combustion air blower.

Draft Control System

Draft control system to monitor the differential pressure between boiler outlet before the draft control damper and atmosphere. Based on a differential pressure preset set point, the system will operate the damper open for purge and based on a preset pressure set point and via a PID loop control the damper will be released to modulate to maintain the set point.

Gas Flow Meter

FLMTR… series Flow Meter Kits reliably measure and display the instantaneous flow of natural gas. A commissioning kit is available to display the current gas flow in SCFH for accurate commissioning of a boiler. Two flow totalization kits are available to measure gas flow and transmit the information to either an LMV52 controller or a PLC.